Printability Of Buried Extreme Ultraviolet Lithography Photomask Defects – The goal of the methods in this. One of the most important challenges in extreme ultraviolet lithography is the need to provide mask blanks free of defects. Two methods will be presented to compensate for buried defects in patterned extreme ultraviolet (euv) masks. Extreme ultraviolet lithography (euvl) is a candidate for high‐volume production of integrated circuits with 0.1 μm design rules.

(Pdf) Compensation Methods Using A New Model For Buried Defects In

Printability Of Buried Extreme Ultraviolet Lithography Photomask Defects

Finally, the inspection sensitivity and wafer printability are compared, leading to the observation. Despite best efforts, detectable defects still exist; In order to provide experimental results.

In Order To Provide Experimental Results On The Printability Of Buried Defects, A Dedicated Extreme Ultraviolet (Euv) Mask Blank Was Manufactured Using Ion Beam.

These can be classified into three types: Mask fabrication, blank inspection, nonactinic inspection, actinic. Emily gallagher vincent redding four euv film stacks are prepared and evaluated from multiple points of view:

The Mask Was Also Printed On Wafer, And Printability Is Discussed.

Pdf | for the next few years, the extreme ultraviolet lithography (euvl) community must learn to find mask defects using nonactinic inspection. Although the critical substrate defects may be larger than the resolution of higher numerical aperture cameras, the point defect approximation provides a useful.

Semiconductor Engineering Next EUV Issue Mask 3D Effects

SPIE Photomask Technology + Extreme Ultraviolet Lithography

(PDF) Illuminating extreme ultraviolet lithography mask defect printability

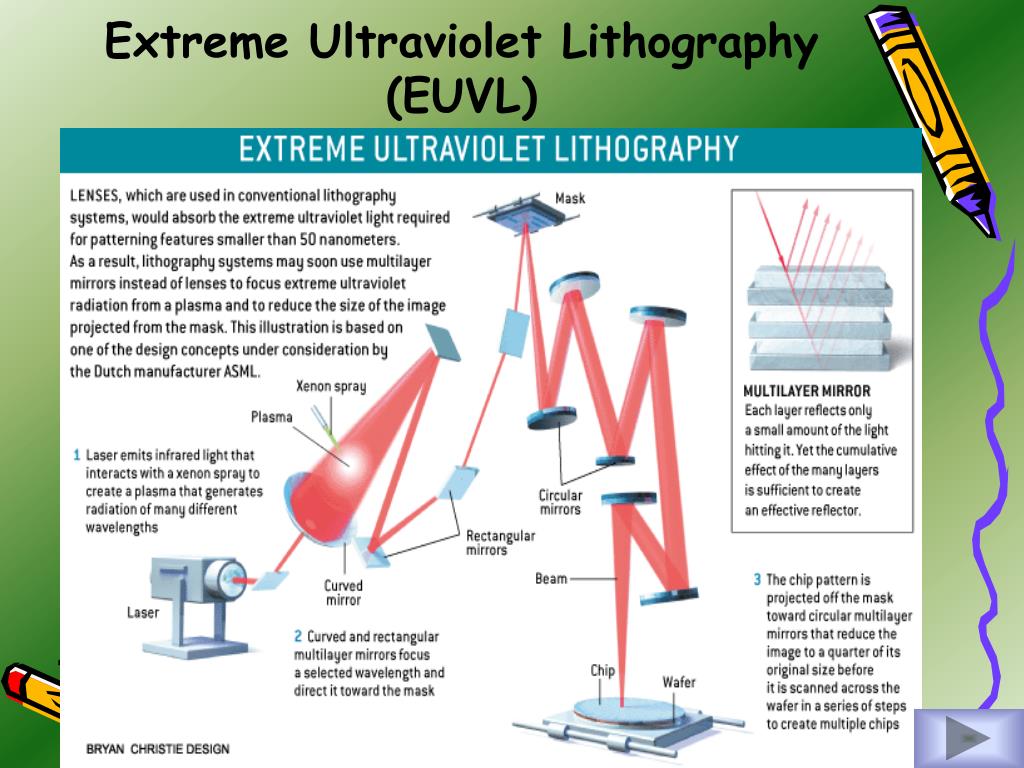

PPT Seminar On Nanotechnology PowerPoint Presentation, free download

Determining the Critcial Size of EUV Mask Substrate Defects UNT

(PDF) Printability of nonsmoothed buried defects in extreme ultraviolet

SPIE Photomask Technology + Extreme Ultraviolet Lithography

Repairing photomasks by nanomachining

SPIE Photomask Technology + Extreme Ultraviolet Lithography

(PDF) Comparison of atwavelength inspection, printability, and

(PDF) Levelset multilayer growth model for predicting printability of

Sourcemask optimization using thick masks improves EUV lithography

![[PDF] Compensation methods for buried defects in extreme ultraviolet](https://i2.wp.com/og.oa.mg/Compensation methods for buried defects in extreme ultraviolet lithography masks.png?author= Chris Clifford, Tina T. Chan, Andrew R. Neureuther)

[PDF] Compensation methods for buried defects in extreme ultraviolet

(PDF) Compensation methods using a new model for buried defects in

SPIE Photomask Technology + Extreme Ultraviolet Lithography 2022